Add : No.340 Sancheng Road, Pingdu, Qingdao, China

Zip : 266700

Website : www.yakaiqiche.com

Product features:

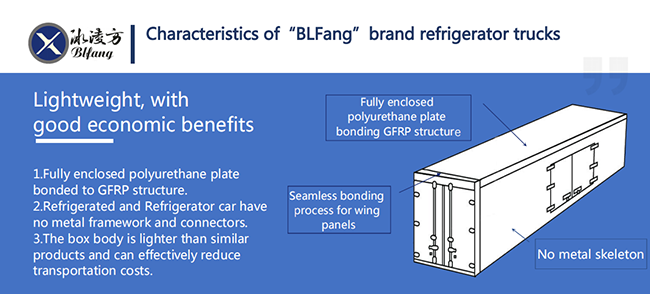

Light weight, good economic benefits

1. Totally enclosed polyurethane plate is used to bond FRP structure.

2. There is no metal framework and connector for refrigerated and insulated vehicles.

3. The car body is lighter than the similar products, which can effectively reduce the transportation cost.

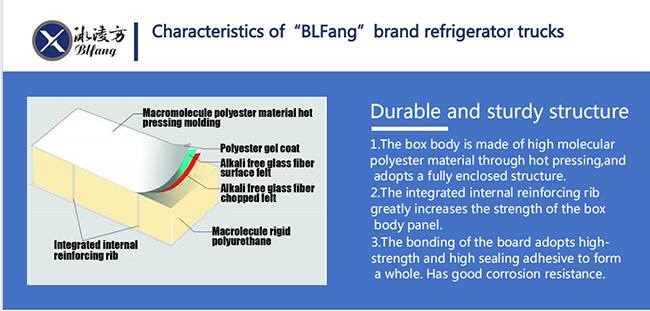

Strong structure, durable

1. The chamber body is made of high molecular polyester material by hot pressing, and adopts a fully enclosed structure.

2. The integrated internal stiffener greatly increases the strength of the panel.

3. The plate is bonded with high strength and high sealing adhesive to form a whole and has good corrosion resistance.

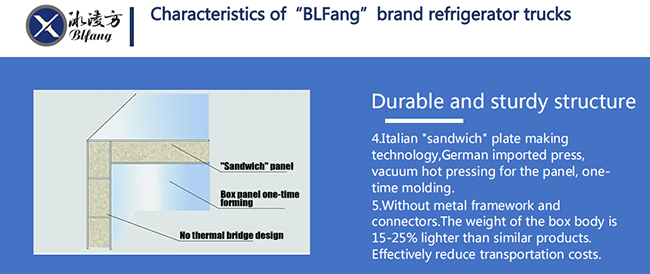

Good thermal insulation performance to meet the transportation needs

1. Sandwich pressing method is adopted to ensure that there is no air gap in the board

2. There is no metal cold bridge and the thermal conductivity is low

Insulated Reefer / Refrigerated Trucks body Factory direct supply

| Term | Insulated truck body |

| Standard thickness | Front/rear/side panel: 83mm |

| roof/floor panel: 103mm | |

| The thickness can be changed according to customer’s requirements. | |

| Dimension of panel | Length 0-15000mm |

| Width 0-3100mm | |

| Height 0-3100mm | |

| Thickness 33, 43, 63, 83, 103mm | |

| Exported to | India, Philippines, Pakistan, Yemen, Singapore, Hong Kong, Thailand, Uzbekistan, Peru, Australia, New Zealand, Tanzania as well as many other countries in Middle East, Southeast Asia, South America and Africa |

| Main characters insulated body | 1. Light in weight: 40% lighter than metal body. |

| 2. Better insulation: K value less than 0.3w/m2k.. | |

| 3. High in strength and long life: 5 times longer than metal body. | |

| 4. Non-corrosion, non-pollution, anti-brine, acid and soda-resisting. | |

| 5. Easy to be assembled and repaired at site | |

| Packing | In CBU (completely built up) and CKD (completely knock down) type |